PRODUCTS

MAGLEV AUTOMATIC SLIDING DOOR

Maglev Automatic Sliding door or linear motor is an electrically-powered motor that instead of rotating it produces a linear force along its length. Thrust is caused through the interaction of magnetic fields within the motors, by magnetic attraction and repulsion.

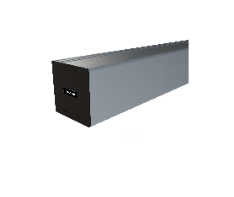

Unlike traditional automatic door drive units, a linear motor drive does not have pulleys, belts, arms and other mechanical elements, resulting in a very compact and stylish housing of 60 x 65 mm, very appropriate for indoor use. The installation process is simplified, while maintenance costs reduce dramatically compared to traditional technologies using DC motors.

Maglev Automatic Sliding Doors are best used for interior doors such as doctor’s clinics, toilet doors, kitchen doors, smoking areas and so much more.

Main technical features

- Compact aluminium housing: only 60×65/70mm (depending on version)

- Minimum clear opening: 750mm Drive length: 1.550mm

- Maximum clear opening: 1.400mm Drive length: 2.850mm

- Leaf weight up to 80Kg

- Adjustable opening speed: 200 to 800mm/s

- Adjustable acceleration and braking curves: 200 to 800mm/s2

- Low operating noise: <50dB

- Power supply: 230/110V AC 50-60Hz

- Power consumption:

In operation 80W

Peaks (0,2 sec) 150W

Stand-by 5W

Motor technical features - Electric three phase AC motor type LSMPM – Linear Synchronous

Motor with Permanent Magnets - Tension: 24V DC (standard); 36 – 48V DC (under request)

- Peak current: 5A

- Operating current: 3A

- Motor driver

Magnetic position feedback with 3 hall cells.

Motion control by means of a driver with field oriented control (FOC)

Wireless communication via Bluetooth

Meet Motion4 - Experts in Linear Motor Technology

Features

Its elegant unobtrusive design allows users to enjoy the safety and convenience of having an automatic entrance without compromising on aesthetics

Powered by magnetic fields rather than mechanical action, the friction is dramatically reduced, which results in a smooth and silent movement.

It is highly sensitive to resistance and obstacles. It can be connected to a wide variety of safety sensors and activation devices, or even set the door in low energy mode.

The absence of belts, pulleys, reduction gears and other mechanical elements commonly used in traditional automatic doors, reduces the need for frequent maintenance and replacement parts.